深圳小步跑科技有限公司ODM服务流程与风险管控优势

Xiaobupao Technology Co., Ltd — ODM Service Process and Risk Management Excellence

一、前言 / Introduction

在消费电子领域,ODM(Original Design Manufacturer,原始设计制造)不仅是制造的延伸,更是整合设计、研发、供应链与品质体系的系统工程。深圳小步跑科技有限公司(Xiaobupao Technology Co., Ltd)凭借多年的行业经验,建立了一套高效且风险可控的ODM服务流程,帮助客户以更低的试错成本、更高的市场响应速度实现产品落地。

In the field of consumer electronics, ODM is more than manufacturing—it is an integrated system combining design, R&D, supply chain, and quality management. Xiaobupao Technology Co., Ltd has developed a highly efficient and risk-controlled ODM process, enabling clients to bring products to market faster with minimized cost and uncertainty.

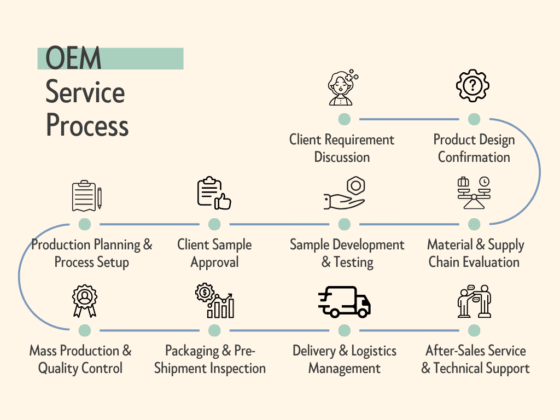

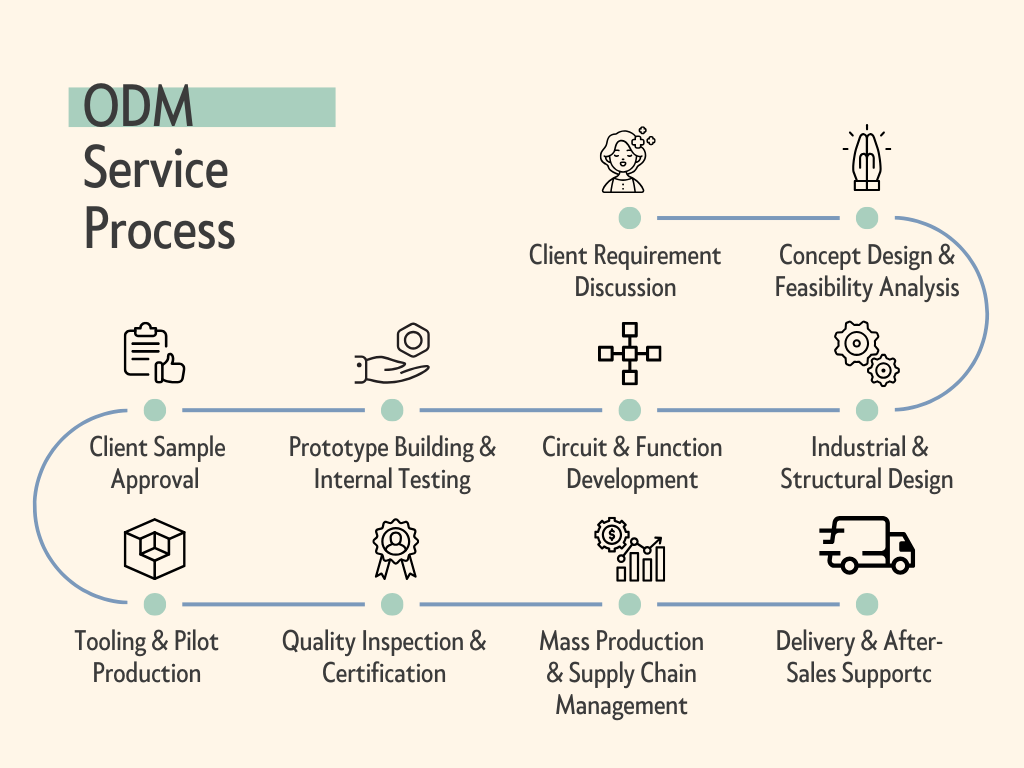

二、ODM服务流程与风险控制 / ODM Process and Risk Control

1. 客户需求沟通 / Client Requirement Discussion

风险控制点:需求不清晰、功能偏差。

小步跑通过“需求澄清矩阵(Requirement Clarification Matrix)”确保客户需求被全面记录与验证。项目初期由双语项目经理主导会议,对目标市场、产品定位、成本边界等进行量化确认,最大程度降低开发方向偏移的风险。

Risk Control: Unclear or inconsistent requirements.

Through a Requirement Clarification Matrix, Xiaobupao ensures that every client’s requirement is fully documented and verified. Bilingual project managers lead the discussions to align expectations on market goals, positioning, and cost boundaries, preventing misalignment at the outset.

2. 概念设计与可行性分析 / Concept Design & Feasibility Analysis

风险控制点:概念过度理想化、成本不可控。

公司通过DFX(Design for Excellence)体系在概念阶段介入工程评估,确保设计的可实现性与供应链兼容性。项目团队使用可量化的风险评估模型(RPN)进行早期验证。

Risk Control: Over-idealized concept, cost escalation.

The DFX framework is applied early to evaluate manufacturability and material feasibility. Xiaobupao uses a quantifiable Risk Priority Number (RPN) model to validate design feasibility and prevent cost overruns.

3. 工业设计与结构设计 / Industrial & Structural Design

风险控制点:结构干涉、装配精度不足。

在结构设计阶段,小步跑采用多平台协同设计(SolidWorks + Creo + KeyShot)并进行动态干涉检测。每一设计阶段输出经过DFMEA(设计失效模式分析)评审。

Risk Control: Structural interference or assembly inaccuracy.

Using collaborative platforms like SolidWorks, Creo, and KeyShot, dynamic interference checks are conducted. DFMEA reviews are embedded into each design milestone.

4. 电路与功能开发 / Circuit & Function Development

风险控制点:电路稳定性与EMC风险。

小步跑内部设有硬件实验室,对EMC、功耗、热管理等进行多维度验证。所有电路板在量产前需通过预认证测试,以确保后期认证环节顺利通过。

Risk Control: Circuit instability, EMC non-compliance.

The in-house electronics lab performs pre-certification tests on EMC, power, and thermal performance. Early detection ensures compliance and reduces later-stage failures.

5. 原型制作与内部测试 / Prototype Building & Internal Testing

风险控制点:样品一致性与验证滞后。

公司设立快速手板与验证中心,可在72小时内完成原型制作。通过标准化的测试报告模板(Test Log Template)实现信息闭环,确保每次改版可追溯。

Risk Control: Inconsistent samples, delayed validation.

The rapid prototyping center delivers functional samples within 72 hours. Standardized test logs ensure full traceability across iterations.

6. 客户样品确认 / Client Sample Approval

风险控制点:样品反馈延迟与修改风险。

小步跑采用数字化样品追踪系统(Sample Tracking Cloud),客户可实时查看样品状态并在线确认。多轮反馈整合通过版本控制系统完成,防止设计混乱。

Risk Control: Feedback delays and revision mismanagement.

Using a digital Sample Tracking Cloud, clients track and approve samples in real time. Version control prevents confusion across feedback loops.

7. 模具开发与小批试产 / Tooling & Pilot Production

风险控制点:模具精度、试产良率。

小步跑拥有模具合作伙伴库(Certified Tooling Partner Pool),每个供应商需通过年审评估。小批量试产通过SPC(统计过程控制)进行首件验证,防止批次缺陷。

Risk Control: Mold accuracy, pilot yield risk.

Certified tooling partners undergo annual audits. Pilot runs are monitored with Statistical Process Control (SPC) for first-article validation.

8. 质量检测与认证 / Quality Inspection & Certification

风险控制点:国际认证不符、抽检误差。

公司配备第三方认证通道(如CE、FCC、RoHS),并引入AI视觉检测系统用于尺寸与外观一致性检查。

Risk Control: Certification non-compliance, sampling deviation.

With certified third-party labs and AI-based inspection systems, Xiaobupao ensures compliance with global standards and dimensional consistency.

9. 批量生产与供应链管理 / Mass Production & Supply Chain Management

风险控制点:供应中断、质量波动。

公司实施ERP+MES双系统联控,实时监测生产节拍与物料状态。关键原料设置双供应源策略(Dual Sourcing)确保连续性。

Risk Control: Supply disruption, quality fluctuation.

ERP and MES integration enables real-time visibility. Dual sourcing secures material continuity and production stability.

10. 出货与售后支持 / Delivery & After-Sales Support

风险控制点:运输风险、售后响应延迟。

小步跑与国际物流伙伴(DHL、SF、UPS)合作,建立出货追踪系统。售后支持采用远程诊断与反馈闭环机制(Service Feedback Loop)提升客户满意度。

Risk Control: Shipping loss, delayed after-sales service.

Global logistics tracking and a feedback loop system ensure timely delivery and efficient after-sales response.

三、核心竞争力 / Core Competence

-

端到端流程掌控 / End-to-End Control:从需求到出货,全部节点可视化、数据化管理。

-

工程与供应链并行 / Engineering-SCM Synchronization:设计与供应同时启动,压缩交付周期30%。

-

风险前置策略 / Proactive Risk Mitigation:采用RPN、DFMEA体系提前识别高风险点。

-

智能化追踪 / Smart Tracking System:云端系统整合设计、试产、物流,实现透明可控。

-

国际标准认证经验 / Global Compliance Expertise:熟悉CE、FCC、PSE、KC等全球认证路径。

四、结语 / Conclusion

小步跑科技以系统化、数据化、透明化的ODM流程,为客户提供可控、可预测、可复制的产品研发与制造路径。通过严格的风险管理体系,公司不仅降低了项目不确定性,更在ODM竞争中建立了稳定、高效的品牌信任。

Through a structured and transparent ODM process, Xiaobupao Technology delivers predictable and controllable outcomes in consumer electronics manufacturing. Its integrated risk management system transforms uncertainty into reliability, defining its competitive edge in global ODM operations.

XBP ODM

XBP ODM